The Problem

Excess humidity in chilled environments causes higher operating costs, loss of turnover and food waste.

Humidity control changes everything.

Prevent breakdowns and reduce your operating costs drastically.

Increase your operational reliability and save on running costs.

Upgrade your cooling and freezer cabinets and rooms with our molecular filter technology.

Your contact: Philipp Draß – Business Development

Are you interested in our products and solutions? Leave us your contact details and we will get back to you as soon as possible.

Copy & paste proven best practices

72% less unplanned downtime in freezer cabinets. More turnover due to less ice & snow on products.

Less ice and snow in the in-store bakery freezer room led to less cleaning and maintenance efforts.

Avoided breakdowns of freezers kept ice cream saleable even during hot summer periods.

Less ice and snow on products and surfaces kept turnover high and prevented breakdowns.

Stable and more even temperatures reduced load on equipment and saved energy.

Colder temperatures improved product quality and reduced the risk of mold and bacteria growth.

Why excess humidity make you pay too much for your operations and lose turnover?

Load peaks on Equipment

High water vapor concentration leads to operational malfunctions followed by food and turnover losses

Ice and snow formation

Excess humidity increases energy consumption because of limited heat transfer and spoils products.

Temperature fluctuations

Load peaks increases energy consumption and chances for growth of mold, bacteria and microbes.

The result

The risk of sudden malfunction up to total breakdowns increases. Wear and tear reduces lifespan of equipment. Food waste and increased operational costs affect your turnover and profit.

Your contact: Philipp Draß – Business Development

Are you interested in our products and solutions? Leave us your contact details and we will get back to you as soon as possible.

Ecologically and

economically worthwhile.

Appear progressive: Using SmartSaver technology not only strengthens your public brand perception and market position, but also your company growth. A balanced cooling process leads to an improved CO2 balance through energy savings, and the amortization often takes place within a year.

Ecologically and

economically worthwhile.

Appear progressive: Using SmartSaver technology not only strengthens your public brand perception and market position, but also your company growth. A balanced cooling process leads to an improved CO2 balance through energy savings, and the amortization often takes place within a year.

One after another is better than simultaneously.

Adsorption instead of condensation: With conventional refrigeration technology, the dehumidification effort by condensation can account for up to 50% of the entire energy consumption. SmartSaver passively regulate the moisture level and thereby reduce energy consumption. First cool efficiently and then dehumidify efficiently.

One after another is better than simultaneously.

Adsorption instead of condensation: With conventional refrigeration technology, the dehumidification effort by condensation can account for up to 50% of the entire energy consumption. SmartSaver passively regulate the moisture level and thereby reduce energy consumption. First cool efficiently and then dehumidify efficiently.

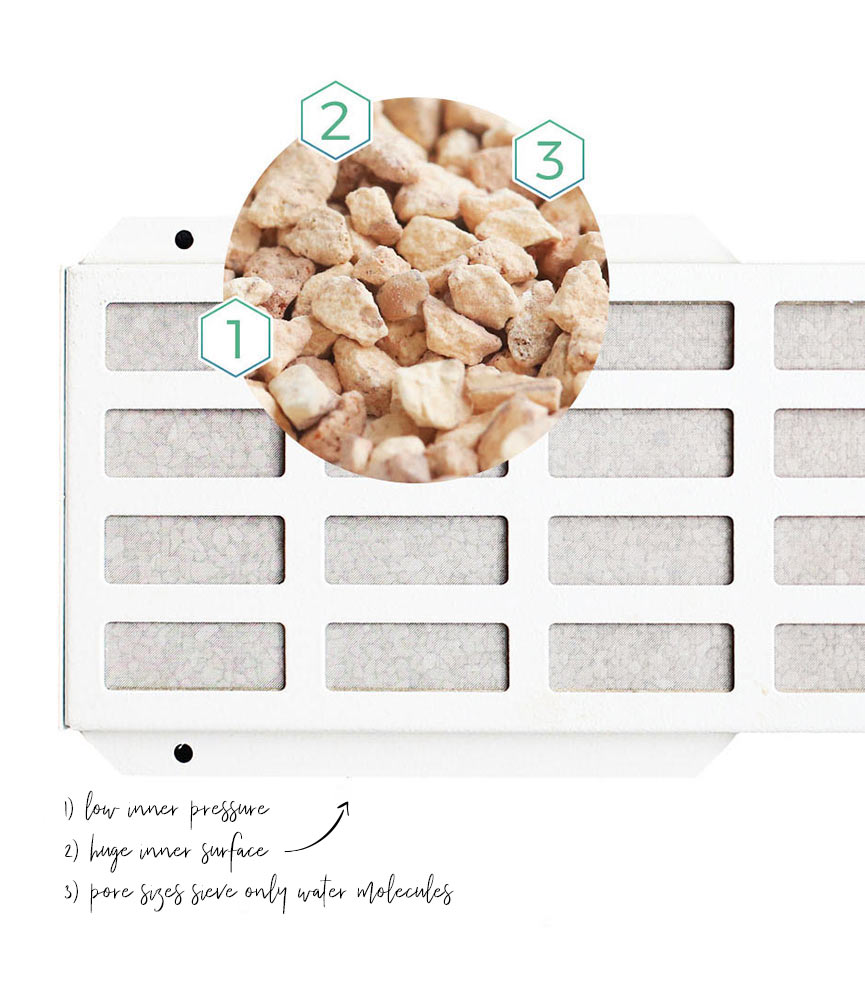

Like a filter.

Unlike any filter.

Unobtrusive and highly effective: They consist of an elaborately processed mineral composition, that completely changes the cooling process. It does not only adsorb humidity of the bypassing air, but also releases it in a dosed manner. It’s completely self-sufficient due to pressure and temperature differences.

Like a filter.

Unlike any filter.

Unobtrusive and highly effective: They consist of an elaborately processed mineral composition, that completely changes the cooling process. It does not only adsorb humidity of the bypassing air, but also releases it in a dosed manner. It’s completely self-sufficient due to pressure and temperature differences.

No ice formation on products, devices and surfaces. Less maintenance. Less wear and tear. Lower CO2 emissions. Longer lifetime.

Every question is a step forward. Let’s talk today and dare the revolution for air conditioning, refrigeration and freezing together with CNT Technology.

Philipp Draß – Business Development

Your contact: Philipp Draß – Business Development

Are you interested in our products and solutions? Leave us your contact details and we will get back to you as soon as possible.

What a typical cooperation with us looks like

Standardized project workflow to get the most out of humidity control in your chilled environment.

Your time commitment: 120min

Your time commitment: 30min

Your time commitment: 30min

Your time commitment: 60min

Your contact: Philipp Draß – Business Development