ZVKKW and the 14th Supermarket Symposium: Humidity control changes everything. We had the honor to speak to a selected audience of professionals on the topic of “Opportunities and chances for more resilient and cost-efficient refrigeration systems in the food retail sector”.

An honor and a challenge at the same time. Just like last week at the Refrigeration Congress of the EHI Retail Institute, Michael Ullbrich, our founder and CEO, was invited to the Supermarket Symposium of the ZVKKW. Only 30 minutes to present complex contexts in front of this select audience of experts, coupled with a little nervousness, could well have led to one or the other message being lost in the process. Therefore, the essential keypoints are summarized again below.

Despite the fact that all parties involved, such as planners, manufacturers, installers and also operators, generally work flawlessly, a wide variety of challenges regularly arise in everyday life. The cause? Deviating usage parameters, which cannot always be simulated by extensive tests according to climate class 3. Excess humidity in refrigerated environments is one of the most common causes of a wide range of malfunctions and losses in the operational use of refrigeration applications (medium temp / low temp)

Visible and invisible problems caused by excess humidity in chilled environments

▶ Problem #1: Ice and snow formation:

Whereas in the sales area, the ice and snow formation on products results in a presentation that is not very conducive to sales, in frozen food rooms it leads to additional cleaning expenses, operational disruptions, staff absenteeism and, in some cases, also impaired occupational safety. The reasons for this are again manifold. On the one hand, it may be that the standard defrost settings are not optimal, that merchandise with too high a moisture load is brought in or, and this could be the most common cause, customers or employees who open doors too long and too frequently when selecting or storing merchandise.

▶ Problem #2: Operational interruptions and breakdowns:

The first problem often leads to the second. If the loads get out of hand, it can lead to increased icing of the evaporator. If the defrosting limits are then exceeded without the ice formation being completely melted away, the problem accumulates to the point of total failure. For the retailer, this often means several days of downtime, loss of goods and turnover, and of course dissatisfied customers.

▶ Problem #3: Food waste and loss of turnover:

According to the Thünen Institute, approximately 11 million tons of food are disposed of in Germany, 7% of which is in the retail sector. This corresponds to approx. 0.8 million tons. Of course, not everything can be attributed to operational problems in the cold chain, and no reliable figures are available. Nevertheless, every retailer can probably report this from his own hand. Of course, it is also the case that this damage to goods is usually compensated by insurance companies. But does that really make it better? After all, valuable resources such as land, energy, personnel and raw materials were used to produce these foods. All of that is disposed of along with the associated sales. That, in turn, is not borne by insurance. Nor will the lost sales during the shutdown be replaced.

▶ Problem #4: High energy consumption:

Load peaks caused by excess humidity increase the total energy required for heat transfer. The more ice and snow that forms on the evaporator, the more the energy transfer is hindered. This leads to longer compressor run times and thus higher energy consumption. As CO2 emissions are usually most influenced by primary energy consumption, high energy consumption inevitably leads to high CO2 emissions in line with the current energy mix.

What does the optimization of conventional refrigeration technology currently look like?

In the context of cooling, the transfer of heat energy is considered. These heat energies are composed of sensible and latent heat. In other words: temperature and humidity. However, when currently talking about the optimization of the refrigeration system, only the temperature is meant and thus all optimization approaches refer exclusively to 50% of the total system. Especially also during the supermarket symposium a lot of this was presented. New refrigerants are used, highly efficient compressors and optimized evaporators as well as condensers are used. Most recently, glass doors have also been retrofitted at open refrigeration cabinets, although even this can be counterproductive and individual operators are already thinking about removing these glass doors. It is true that the heat input through the doors is limited. Nevertheless, the dehumidification performance may no longer be sufficient and unwanted condensation may form on products and surfaces.

In conventional systems, this problem cannot even be detected. The reason: sensors and measuring probes are installed exclusively for temperature. In terms of food safety and HACCP, this is of course also crucial. However, for efficient equipment operation, it is not sufficient to measure and optimize only 50% of the overall process.

Regenerative processes for humidity control

Adsorption and desorption processes always run simultaneously until a state of equilibrium resulting from the ambient conditions has been reached. Due to temperature and pressure differences, this equilibrium can be shifted more strongly in the direction of adsorption or desorption. The sorption potential of the respective system is often represented in diagrams showing the energy potential of a molecule at a distance from the surface. Curves are composed of repulsive and attractive interactions and depend on the molecule as well as the surface geometry; these can be determined, for example, via quantum chemical calculations and molecular dynamics simulations.

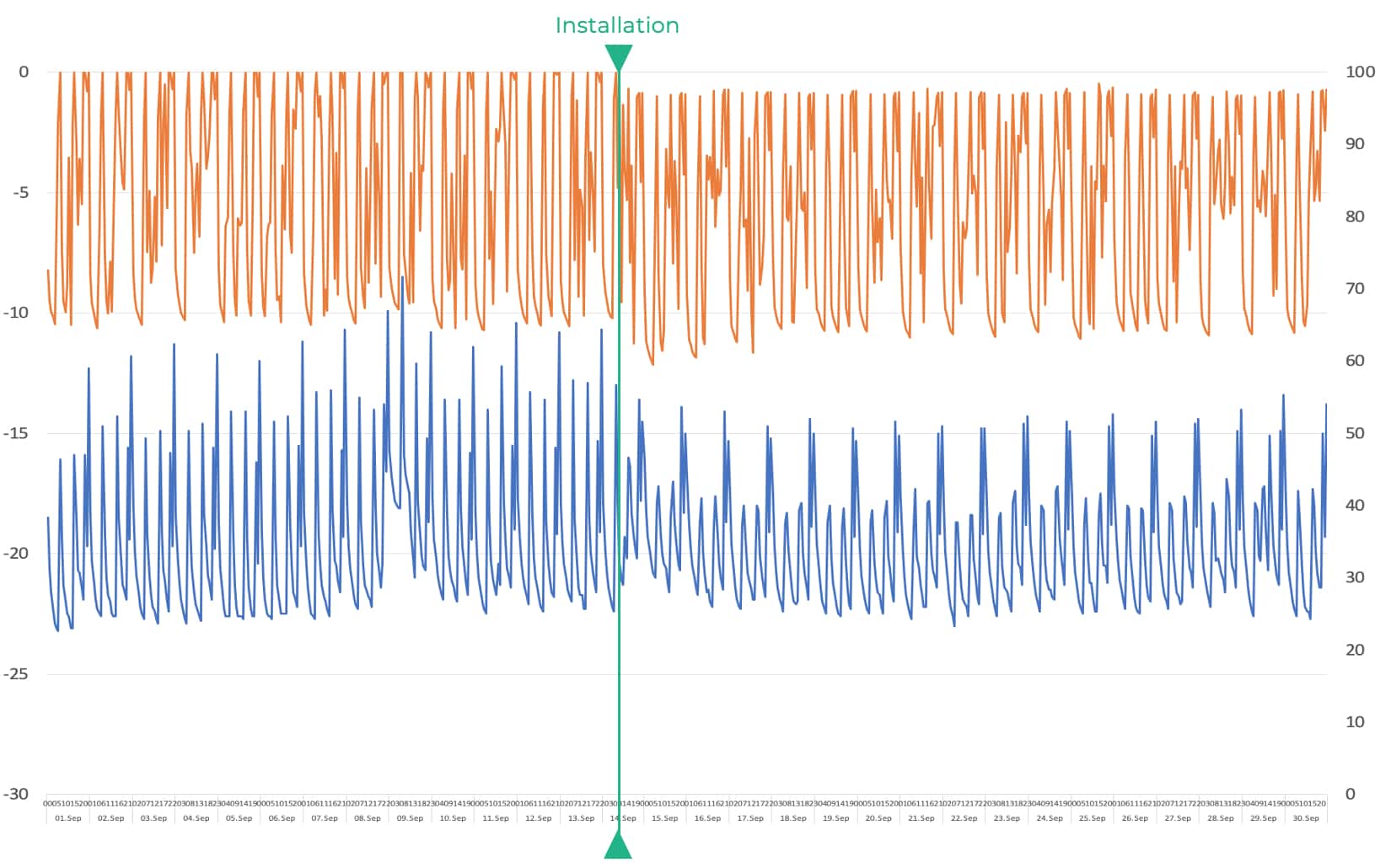

You can clearly see how the use of our molecular filter affects the overall performance of the cooling system. Above in orange you can see the relative humidity, which regularly reached 100% before installation and thus led to unwanted condensation. Below you can see the temperature in blue, which showed a much smaller fluctuation range after installation. More stable temperatures lead to better product quality and lower loads on the compressor.

By using our molecular filters, you achieve less:

Operating Costs

Breakdowns

Food Waste

Ice and snow

Maintenance

Energy Consumption

The dangers of excessive humidity in supermarkets are often overlooked, but their impact on operations, profitability and customer experience is undeniable. By harnessing the revolutionary power of a molecular filter, you take control of your supermarket’s destiny. Uninterrupted operations, minimized food waste, reduced costs, improved customer experience and long-term profitability await those who dare to challenge the status quo.

Contact

Do you have any questions about “Supermarket Symposium”? Then write to us. Or contact us directly on LinkedIn. Add us there as an interesting page, so that you will not miss any news in the future. We will answer you promptly.